Premiere Inc. - The Casing Running Experts

The Benefits of Casing Running Tools • Premiere Inc.

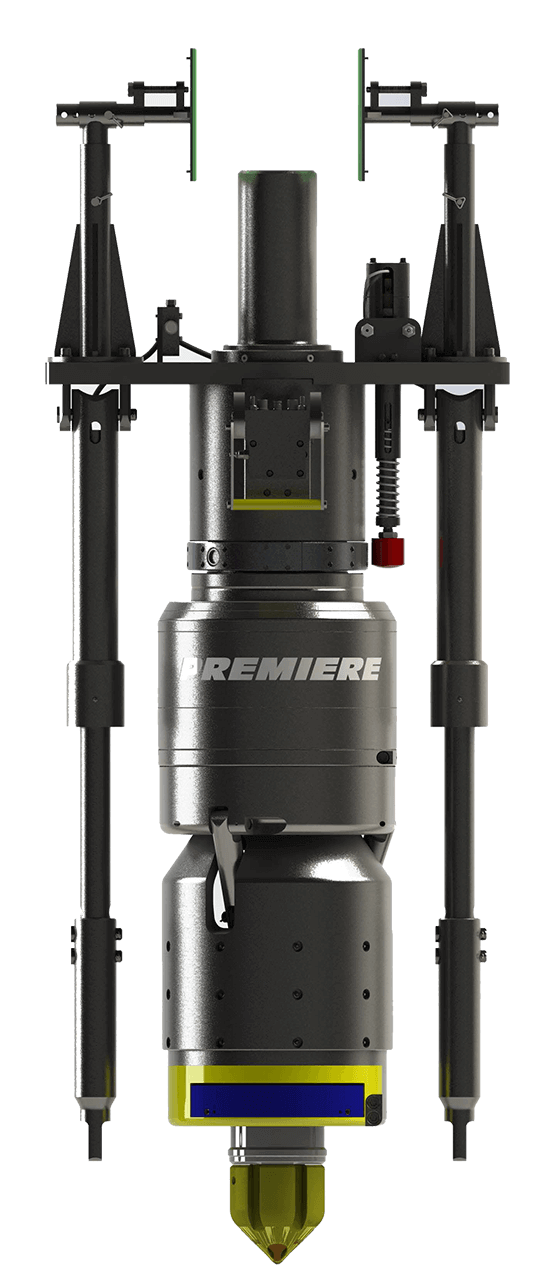

What’s safe, cost-effective, and virtually eliminates the dropping of pipe during casing operations? The casing running tool, or CRT, is connected to the top drive system, so a drilling crew can easily operate strings of casing without a lot of extra equipment or people.

Every drill crew is familiar with the top drive systems that drill wells. Now, these top drives are utilized by the same drilling crew to make up and run casing strings. No one has to babysit the casing stabbing board. Instead, the top drive supplies the torque to make up the connection so casing tongs, bails, elevators, and stabbers are no longer needed. The result? Fewer people on the rig floor while it’s operating and faster, safer casing runs.

The biggest lost-time incident operation has always been the stabbing board operator. The CRT eliminates this safety hazard. With less manual interference, safety is improved across the board. Less risk of cross-threading ups the safety factor, and efficiency level, even more.

How the Casing Running Tool Works

The top drive system and CRT are installed by the rig manager before casing operations. This tool includes a set of slips, like those found in the usual elevators and spiders, and the size is chosen based on the size of the casing to be done.

These slips can handle the full weight of the whole casing string—that’s up to 500 tons, and can transmit the torque necessarily to make up the casing connections, up to a whopping 35,000 foot -pound at 2,000 psi.

Joints of the casing are lifted to the well center by a single-joint elevator that’s supported by the CRT. Every one of the joints are stabbed into the joint before it at the well center. The CRT and top drive are then lowered until the CRT is on the new addition, then topped automatically on the joint ofcasing. Once these slips are set on the joint of the casing, the top drive is energized, using the needed torque through the casing running tool to the casing connection.

A manual backup tong is unnecessary and, as such, is no longer needed on the rig floor. Casing strings fill up—without stopping the run. The remotely operated control panel is easy to use and allows total control of the tool for one person, lowering the risk of a dropped pipe.

Safe and Efficient

First casing runs with the CRT are particularly fast, especially when compared to the typical three hour rig down time needed for the traditional tongs and similar equipment. It saves time—and money. No extra drill crews are required. With less people and less equipment on the drill floor, there’s less chance of safety risks and hazards too. It’s a powerful, in-house, modular design and an indispensable tool in the oilfield.