Premiere Inc. - The Casing Running Experts

Successful Cementing Services: Best Practices • Premiere Inc.

Cementing services support and protect well casings and help with zonal isolation—critical to safer, environmentally sound, profitable wells. Accomplishing this safely, efficiently and successfully doesn’t mean you have to reinvent the wheel. In fact, the basic steps for completion of cementing jobs haven’t changed for over 60 years.

Here we’ll go over the eight steps you can take to ensure you’re completing your cementing job well every time.

1. Condition the drilling fluid.

To make sure that you have good fluid mobility after running the casing, figure out the hole volume that can be circulated and evaluate the percentage of wellbore being circulated. You also want to make sure you’re circulating the drilling fluid to break its gel structure and conditioning the fluid until it reaches equilibrium.

2. Employ spacers and flushes.

To achieve effective mud displacement with spacers and flushes, you want to use a series of guidelines to optimize flow rate, contact time, and fluid properties. To do this, you should pump spacer fluid as fast as possible without breaking down formation, and design your spacer package to wet the pipe’s surface and formation completely.

3. Move the pipe.

You should rotate and reciprocate casing in order to break up gelled drilling fluid. At lower pump rates, these pipe movements can keep drilling fluid flowing.

4. Centralize the casing.

Casing with mechanical centralizers across isolated intervals better displaces drilling fluid. If the casing is not centralized, cement can bypass drilling fluid by moving down the wide side of the annulus and leaving drilling fluid in the arrow side. Proper pipe standoff also makes uniform flow patterns around the casing.

5. Maximize displacement rate.

The best way to ensure good mud displacement is by creating turbulent flow around the full casing circumference. While not always possible, especially for formation and wellbore configurations, you should always use the highest pump rate feasible for your project.

6. Mix slurry at the right temperature.

A number of factors affect the time it takes for slurry to thicken, as well as its set time and compressive-strength development. You should design your job based on wellbore circulating temperatures taken with a downhole temperature sub recorder. Use this temperature to apply the correct amount of dispersants and retarders.

7. Test cement composition..

The best cement slurry doesn’t have free water, has enough retarder for proper placement and a stable density, and provides sufficient fluid-loss control. The best way to ensure proper consistency is by adding just enough fluid-loss control materials.

8. Select the proper cementing system.

While cementing systems are often similar, they provide different capabilities of zone isolation in changing environments. Good isolation is determined by seeing whether or not the cement system can provide zone isolation for the life of the well. Consider which type of cement system – for example, foam cement – can withstand the stress of casing expansion and contraction.

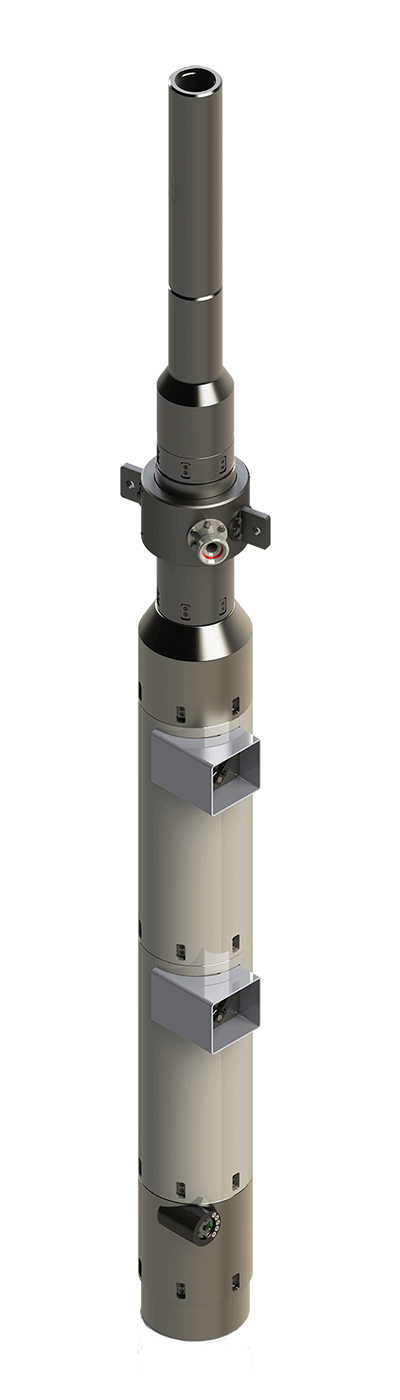

If you’re looking for accuracy and precision every time in your cement jobs, the Premiere Rotating Cement Head (RCH) could be the tool you want. The no leak swivel design allows for circulation and rotation at high RPMs for long periods. The RCH can be built to fit your unique cementing needs.Contact Premiere, Inc. today to see how the RCH could make your cement jobs reach their simpler and more efficient completion.